16

17

Vulcan

Winter

2013

It was clear I needed to take a decision:

the project now demanded my full-time

attention. Should I stay in employment

at Cisco Systems, or take a leap into

an uncertain future leading the Vulcan

restoration? How many chances in life

does one get to make such a unique

contribution? At the beginning of April

2000, I resigned from Cisco.

Costings showed that about £3.5million

would be required. After two applications

and considerable public support, in

June 2004 the Heritage Lottery Fund

confirmed the award of £2,734,000, with

the rest to be raised by ourselves. An

18-person technical team was recruited,

and put through a 13-week Vulcan-specific

technical training course. Finally, in

August 2005, following the necessary

CAA approvals, work started.

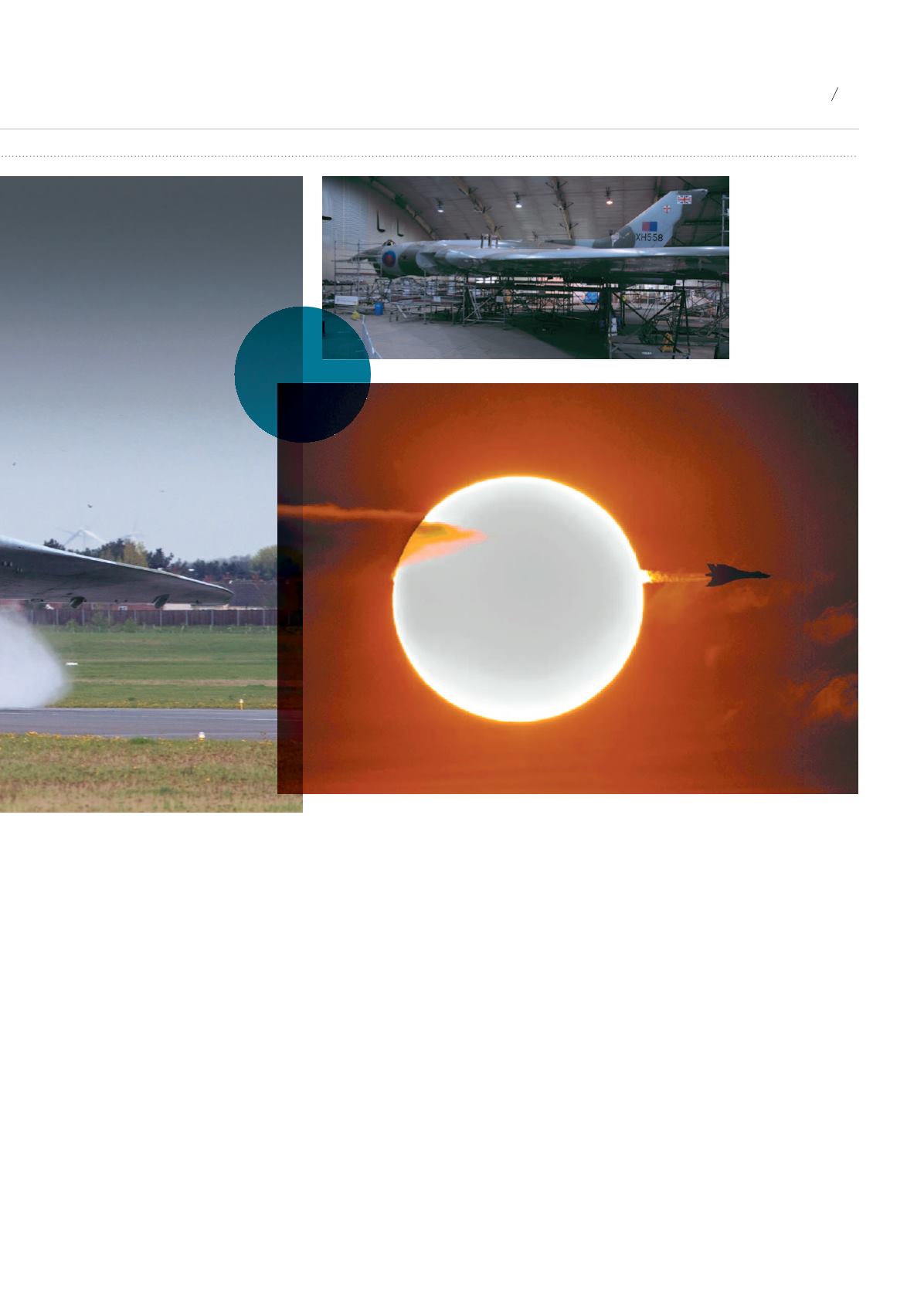

Restoration

The restoration was to have four phases

starting with a detailed inspection of the

aircraft for faults, followed by rectification

of those faults. During this period, the

hundreds of components were overhauled

and returned for the recovery of the

aircraft to the correct configuration for

flight. Tests followed, first on the ground

and then, with ticks in all the boxes, the

aircraft was released for its first test flight.

For the inspection, virtually everything

that could be removed from the aircraft

was removed, requiring a major exercise

to track each component. Every aspect

of the aircraft’s structure was inspected

visually, and non-destructive techniques

were used to discover any underlying

problems. Numerous repairable faults

were found, including skin cracks,

missing rivets and corrosion, but none so

significant to warrant concern.

The aircraft’s hydraulic, pneumatic

and oxygen systems were removed for

inspection and overhaul. All flexible pipes

and seals were replaced, an expensive

effort on its own. The Vulcan has many

critical systems powered by electricity,

including the flying controls, so the

integrity of the electrical system is vital:

the aircraft was rewired.

Recovery and Testing

With structural work nearing completion

in the Spring of 2007, attention focused

on refitting the aircraft’s systems. The

components taken off for overhaul were

refitted: from canopy to landing gear,

from engines to powered flying control

units – the list went on and on. With

the exception of modern avionics, the

restored XH558 is almost completely

authentic.

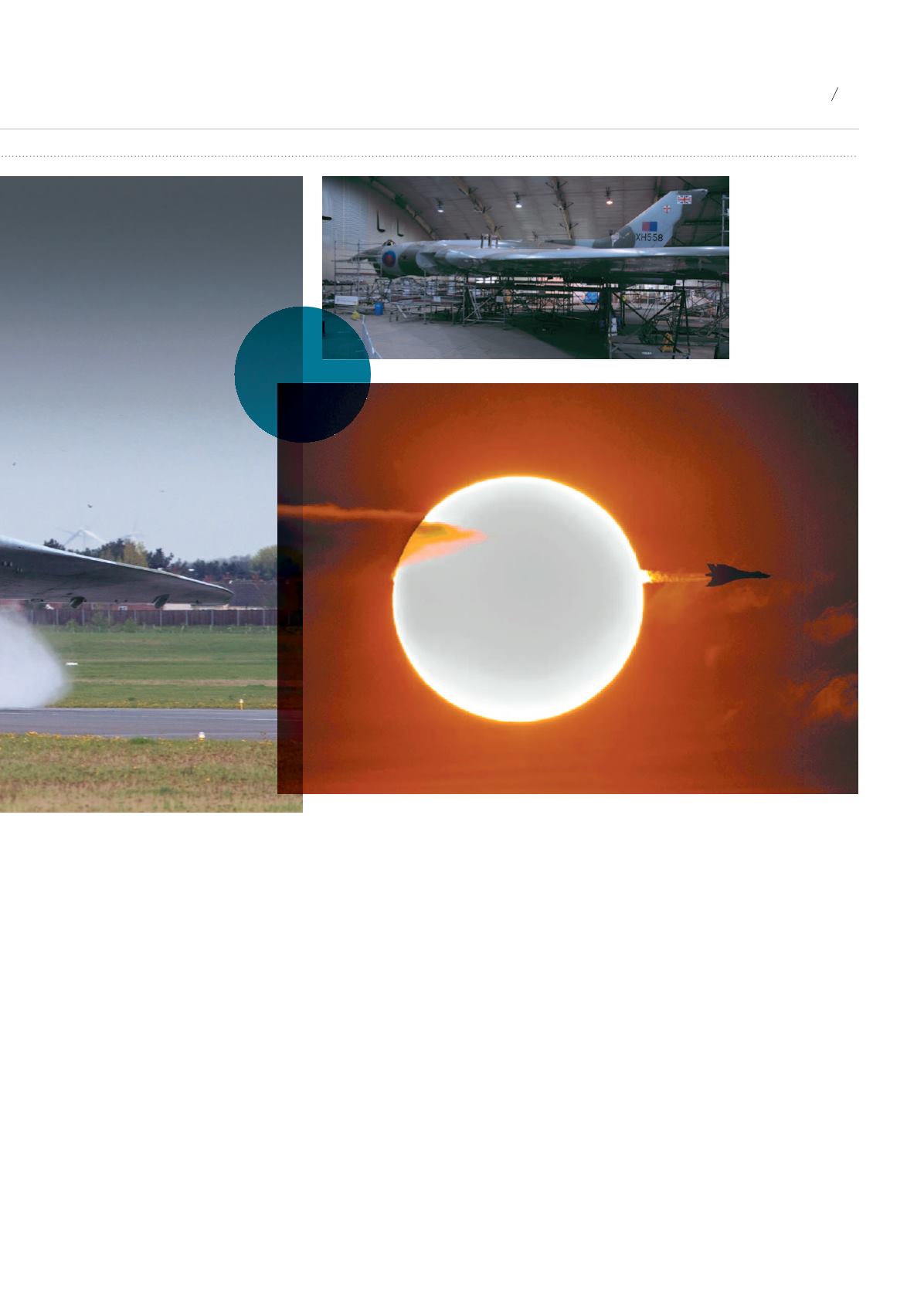

Ground testing started in early summer

of 2007 with the application of electrical

power. One by one, the various systems

were put through procedures to ensure

correct operation. August arrived: it was

time to light the fires! The four Olympus

engines were started and performed

perfectly – over 25 years since they were

last run. It would be wrong to imply that